Overview

This is a TPS/Lean training tour for construction fileld. You will learn the philosophy and introduction method of TPS/Lean and inspect the construction site.

Date : April 12, 2020 (Sun) ~ April 18, 2020 (Sat)

Meeting : Central Japan International Airport (Aichi Prefecture) or Hotel in Nagoya

Tour ends : Tokyo city or Narita Airport

The point :

| ✓ | TPS training by consultant who background at Toyota Motors or group companies. |

| ✓ | Visit factories and construction site. |

| ✓ | Japanese-English interpreter |

| ✓ | Transportation during the tour |

| ✓ | Hotel Accommodation for 6 nights (with breakfast and lunch included also 2 times diner only) |

The main purpose

1 Improve work efficiency

2 Reduce disasters

3 The latest technology

The TPS/Lean for construction site

TPS(Toyota Production System)/Lean is based on the philosophy of the complete elimination of all waste in pursuit of the most efficient methods.

The concept of TPS is also effective in the construction industry.

For construction company,The concept of TPS and its approach to cost reduction is effective to gain competitive strength.

About our TPS training center

The TPS traning center( Hirayama Training center) originally started from giving basic TPS operation training to employees assigned to work at Toyota Motors or group companies, and have been making remarkable output. Activities of the training center evolved and currently the main purpose lies in spreading TPS Kaizen method domestically and globally, supporting educational and training programs.Until present, more the 8,200 participants from 30 countries have attended.

Earthquake-resistant technology

The seismic standards were revised in 981, and currently, 75% of Japanese buildings are earthquake resistant, but are still improving to 90%.

Earthquake-resistance < Vibration control < Seismic isolation

In Japan, where there are many earthquakes, it has been reported that the performance of seismic isolation is higher than the other two for each major earthquake. (Although the cost of seismic isolation will of course be higher)

Recycling of construction waste

In Japan, the government and companies conducting business toward the realization of a sustainable society. It may be its mission to reduce waste and recycle and utilize it in Japan where the land is narrow and resources are scarce.

It is said that the final disposal of industrial waste is very difficult.

But in a Japan, Industrial Waste company are good at recycling it.

The Japanese construction industry is faces with a super aging society.

Until now, women and aging workers were not working at construction sites in Japan, but the construction industry is rapidly changing to workable systems. Foreign workers who have refused are also adding laws temporarily and actively adopting them.

Sales ranking 2019 /Construction industry in Japan

| Company | Sales | Employees | |

| 1 | Daiwa House Industry Co., Ltd. | 4,143,505 million yen | 16,670 |

| 2 | Sekisui House, Ltd. | 2,160,316 million yen | 16,538 |

| 3 | Obayashi Corporation | 2,39,685 million yen | 8,753 |

| 4 | Kajima Corporation | 1,974.269 billion yen | 7,783 |

| 5 | SHIMIZU CORPORATION | 1,664.96 billion yen | 10,714 |

Recommended for people like this

Tour Remarks

Cancellation Policy

-

※ The handling fee for refund will be paid by the customer.

※ If the number of people in the hotel room or the room type changes due to a reduction in the number of participants, additional charges will be required.

Person in charge

Miki Shimizu

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

Dates & Price

Tour Code: ci12-7d

DAY 1

Welcome to Japan

12/04/2020- -----

-

We will be waiting at the arrival airport. Check in to hotel.

Overnight: Nagoya | Dinner

DAY 2

TPS training center

13/04/2020- -----

-

About TPS and Lean

Nearly 30 years ago, Lean was presented as the generic version of TPS.

Actually, Lean was an interpretation of TPS – a rather poor interpretation.

Then, over time, Lean drifted farther away from TPS, thus making it far less of a generic version of TPS and more its own unique thing.“Difference”

The lean production method is packaged even as a production management method, and a set of texts, checklists, and standards required for introduction is provided as a package from a consulting company. - -----

-

TPS – Do you really understand what is waste? –

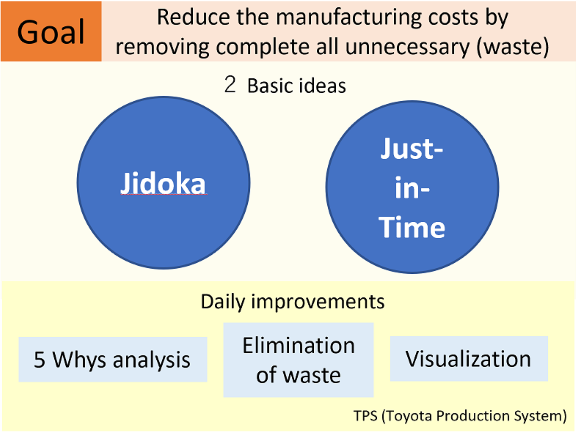

The basic philosophy of TPS(Toyota production system) is the reduce the manufacturing costs by removing complete all unnecessary (waste).There are two basic ideas.

1) jidoka

“jidoka” is not just automation.

“jidoka” (which can be loosely translated as “automation with a human touch”), as when a problem occurs, the equipment stops immediately, preventing defective products from being produced.

Avoid making defective products, rather than finding defective products by inspection.2) Just-in-Time

Making only “what is needed, when it is needed, and in the amount needed”

Just-in-Time is a production method that responds to diversifying consumer needs. Even in small-lot production of many kinds, work in process can be eliminated, and production can be performed with less cost and in shorter time.Etymology of Just-in-time

A word from Toyota Motor’s founder Kiichiro Toyoda: “Car parts are best collected just in time.”

- -----

-

About TPS traning

- Improve your skills and techniques by our well equipped training facilities and vastly experienced staffs.

- Learn the philosophy of lean management and manufacturing, TPS principles and Gemba Kaizen. (Continuous improvement in work place)

- Improve yourself learning and analyzing your movement through installed model line and standard operational combination list.

Overnight: Nagoya | Breakfast,lunch

DAY 3

Factory tour for TPS/Lean

14/04/2020- -----

-

We visit two factories a day. Please contact us if you would like to know about the visiting factory.

Example

Company : Toyota Motor Corporation

Establishment : 1937

Location : Aichi Prefecture

Main Business : AutomotiveThe Toyota Production System is considered to be the final production control method, which has led Toyota to be the most competitive motor company in the world.

Every company in the world is interested in whether to implement the Toyota Production System to their system. - -----

-

Toyota factory

During the tour, visitors will be shown the Assembly Plant.Notes on factory tours.

If you do not observe the precautions, the factory tour will be canceled.- Photographs on the factory premises, VTR

- Bringing electronic devices such as cameras, mobile phones, Wi-Fi routers, etc. into the factory buildingSmoking, eating and drinking (only water bottles with lids and plastic bottles can be brought in for hydration)

- Sandals, footwear such as high heels over 5cm

- Drinkers

- Children under 6 years old and children under 12 years old without parental supervision·

- Passenger who factory arrival on car or foot, admission.

Overnight: Shizuoka | Breakfast,lunch

DAY 4

The construction site tour

15/04/2020- -----

-

Arrive at the barrier to prevent landslides.

Example

Visit one of Japan’s largest erosion control facility. It is a erosion control facility at the foot of Mt. Fuji. Debris flood caused by debris flows and snow charges was captured by erosion control facility and sedimentation works to prevent disasters in downstream areas. - -----

-

Overnight: Tokyo | Breakfast,lunch and Dinner

DAY 5

The construction site tour

17/04/2020- 10:00

-

Example

Arakawa River Control

Rivers change greatly with the growth of the city.

A catastrophic flood occurred in Arakawa in 1910.

Fundamental flood control measures were planned through this flood, and dredging was completed over 28 years. Since then, straightening of the channel and strengthening of the embankment have been performed to this day.Overnight: Tokyo | Breakfast, lunch

- 14:00

-

The number of participants and the tour schedule determine where you can visit.

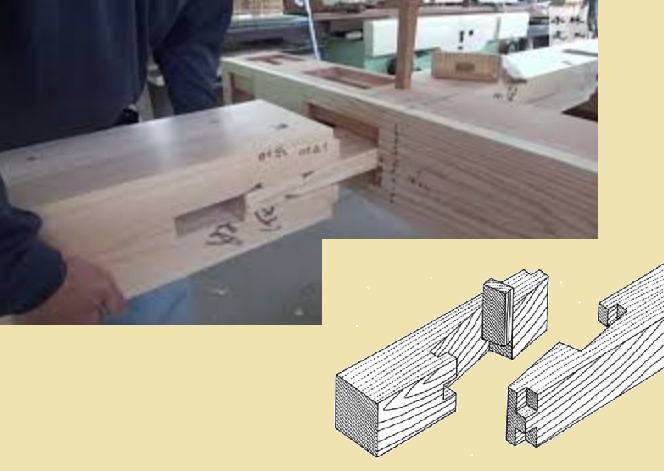

Tokyo Mokkoujou by SHIMIZU CORPORATION

A rich heritage of woodworking skills handed down since the days of temple and shrine carpenters.

Tokyo Mokkoujou Arts & Crafts Furnishings at Shimizu has refined and passed down traditional skilled techniques used by woodworkers since it opened in 1884.

About 80% of Japanese houses are wooden.

Japanese wooden architecture still uses traditional techniques.In order to fix the tree to the tree without screws and nails, cut the tree exactly and connect it with its part.

Wooden buildings are lighter than other materials, so they are less susceptible to earthquakes and can withstand a magnitude 7 earthquake.

Japanese traditional architectureOvernight : Tokyo | Breakfast ,Lunch and Dinner

DAY 6

Submarine tunnel and Seminar

18/04/2020- -----

-

The Tokyo Wan Aqua-Line Expressway

[Overview]

Road Name: Tokyo Wan Aqua-Line Expressway

Road Number: National Highway No.409

Road Length: 15.1 km

Total Construction

Cost: Approx. 1.44 trillion

yen

Date Opened: Dec. 18, 1997[Tokyo Wan Aqua-Line’s construction]

The Tokyo Wan Aqua-Line Expressway consists of two-10km long tunnels (Aqua Tunnel) under Kawasaki waters and a 5 km long bridge(Aqua Bridge) over Chiba waters with two artificial island in between.

Japan’s first marine rest area “Umihotaru” is an artificial island constructed to shift the expressway from the tunnels to the bridge.

There is also a tunnel ventilation tower callded “Kazenotou (Tower of Wind),” on the artificial island in the mid-section of the undersea tunnel and a pyramid shaped Ukishima Ventilation Station near the tunnel entrance on the Kawasaki side. - 14:00

-

Visit and Seminar

Construction Technology Exhibition Hall (Ministry of Land)- Disaster measuresLatest

- Civil engineering

- Seismic technology

Or

Recycling of construction waste

The technology of the Japanese construction industry, which is environmentally friendly, can be confirmed in waste disposal.Overnight : Tokyo or Narita| Breakfast and Lunch

DAY 7

Return Day

19/04/2020- -----

-

We will send you to the departure airport.

Destination

Aichi

Aichi Prefecture where there is Toyota city famous for Toyota. It is located between Tokyo and Osaka, has a large international airport and a Shinkansen station, and is very convenient for transportation. And Aichi Prefecture is adjacent to 4 prefectures. (Mie, Gifu, Nagano, Shizuoka) For sightseeing, Toyota Motor's Museum, Atsuta Jingu Shrine, Tokugawa Art Museum, Nagoya Castle, and Inuyama Castle are popular.

Reviews

Very professional approach

Auto parts

USA 18 people

We would like to take a moment to thank you for such a very professional tour.

Each factory tour and TPS traning were all very professional and informative. We learned so much about lean as well as experiencing the Japanese culture and the amazing people.Not only were the days but the nights were fun.

This tour has been the best tour we have ever been and we would like to be sending more of our team.

JP-EXPERT's buisiness tour made our time in Japan unforgettable.

University

Russia 29 peopleJP-EXPERT's buisiness tour made our time in Japan unforgettable. We were able to visit most of the companies we requested, but the spelndour of japanese companies and people were far beyond our imagination.

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays