Overview

In November, the autumn leaves season, we will hold the tour for learn Kaizen from training in TPS training center and visiting factroy.

This is a 2-day tour. This is a special price tour with a fixed schedule. Training by Consultants with a Toyota Background. It is possible to pick up and drop off at hotels in Nagoya city or Toyota city.

Schedule

Date November 5 (Tuesday) and November 6 (Wednesday) 2019

Content TPS training center and factory tour for learn Kaizen

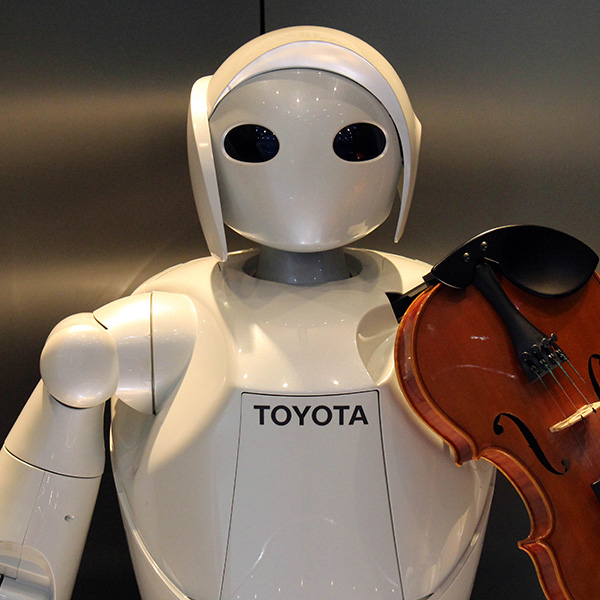

About TPS training center

In this course we will:

1) acquire the ability as managers & supervisors to execute Kaizen by yourself

2) acquire TPS fundamental knowledge

3) execute Genchi, Genbutsu principle and see actual work site of skills to detect MUDA, MURA and MURI

4) experience and master Kaizen technique by executing motion analysis using the model production line.

Recommended for people like this

Because the schedule is fixed, you can learn about TPS in earnest at a very reasonable price.

By visiting two factories on the day after the training, you can better understand the kaizen.

Tour Remarks

Cancellation Policy

-

※ The handling fee for refund will be paid by the customer.

※ If the number of people in the hotel room or the room type changes due to a reduction in the number of participants, additional charges will be required.

Person in charge

Miki Shimizu

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

Dates & Price

Tour Code: k13-2d

DAY 1

TPS training center

05/11/2019- -----

-

We will pick you up at your hotel and go to TPS-training center

- Training by Consultants with a Toyota Background.

In this course we will:

1) acquire the ability as managers & supervisors to execute Kaizen by yourself

2) acquire TPS fundamental knowledge

3) execute Genchi, Genbutsu principle and see actual work site of skills to detect MUDA, MURA and MURI

4) experience and master Kaizen technique by executing motion analysis using the model production line.About TPS and Lean

Nearly 30 years ago, Lean was presented as the generic version of TPS.

Actually, Lean was an interpretation of TPS – a rather poor interpretation.

Then, over time, Lean drifted farther away from TPS, thus making it far less of a generic version of TPS and more its own unique thing.

“Difference”

The lean production method is packaged even as a production management method, and a set of texts, checklists, and standards required for introduction is provided as a package from a consulting company.

On the other hand, TPS is a production method that has been established to thoroughly eliminate waste on the production line.

It is a method that has been systematized based on the two pillars of “just-in-time” and “automation” in order to define seven wastes and eliminate them.

DAY 2

Visit the factory

06/11/2019- -----

-

Example of a visit

We will tour the factory to learn about the production techniques of excellent Japanese factories such as KAIZEN and safety and health.

Destination

Aichi

Aichi Prefecture where there is Toyota city famous for Toyota. It is located between Tokyo and Osaka, has a large international airport and a Shinkansen station, and is very convenient for transportation. And Aichi Prefecture is adjacent to 4 prefectures. (Mie, Gifu, Nagano, Shizuoka) For sightseeing, Toyota Motor's Museum, Atsuta Jingu Shrine, Tokugawa Art Museum, Nagoya Castle, and Inuyama Castle are popular.

Reviews

The consultant's seminar was good!

Food processing plant

Singapore 8 people

am interested in recycling industrial waste personally and participated in the seminar tour.

The industry is different, but I was surprised to see the recycling factory.

Not only that technology but also management that leads to raising the problem was wonderful.

I was able to know Japanese environmental technology.

Manufacturing industry

Vietnam 20 people

In order to reform our factory with the aim to create an environmentally conscious factory,

I visited a Japanese company for our reference.

Satisfied with medical checkups and hot springs.

Parts processing company

China 4 peopleI could spend less time to stay in Japan effectively. The place to visit was inconvenient to access by myself. That's why I participated in the tour and I was also able to attend consultant seminars.

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays