Overview

A training tour to understand the points to Kaizen in your factory

We offer seminars, on-site Kaizen training and companies visits where you can check the structure and management of the Toyota Production System.

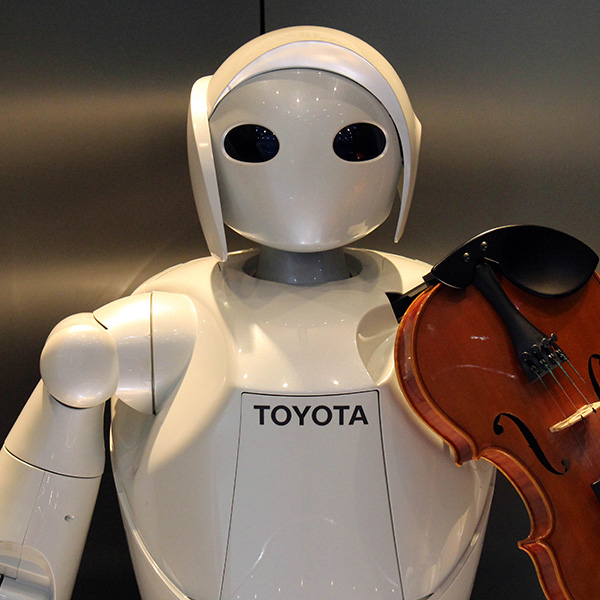

About TPS training center

Our TPS Training Center was established under the guidance of the Toyota Motor Training Center Director.

Abut TOYOTA

Japan’s leading car manufacturer, Toyota, has its headquarters and many of its domestic production plants in the region around Nagoya. The company’s headquarters are located in the city of Toyota, less than one hour east of central Nagoya.

So you can visit factories implement the Toyota Production System to their system in Toyota-city.

Lean and TPS

The lean production method was born from TPS, so TPS and Lean are almost the same, but please understand the difference in historical background and consider the introduction method that suits your company.

Recommended for people like this

Those who want to learn about TPS and KAIZEN, or who want to improve their factories.

Tour Remarks

Cancellation Policy

-

※ The handling fee for refund will be paid by the customer.

※ If the number of people in the hotel room or the room type changes due to a reduction in the number of participants, additional charges will be required.

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

Dates & Price

Tour Code: K19-6d

DAY 1

Arrinved at Kansai Airport

- -----

-

Arrived at Kansai Airport.

A guide will be waiting for you at the airport and will guide you to the hotel in osaka.

DAY 2

Go to aichi

- 10:20

-

A guide will guide you from the hotel to Shin-Osaka Station.

Depart from Shin-Osaka Station

- 11:10

-

Arrived at Nagoya Station.

- 13:30

-

Toyota Techno Museum.

The museum, located adjacent to Toyota global headquarters, is a showcase of Toyota’s philosophy and corporate direction.

Areas of the museum cover environmentally friendly cars, safety and mobility, “Good Thinking, Good Products” (TPS), Toyota in society, motor-sports, and a display of the latest models from Toyota and Lexus.

The TPS area in particular is a popular area for participants of this tour to gather and learn directly from Toyota about how it explains its system.

DAY 3

TPS training center

- -----

-

In TPS training center

TPS training center is Hands-On training at Kodel Production line.

Instructors with actual experience serving as key players at Toyota Motors Production will pass on the tps kaizen, which Japan can be very proud of, at its unique facility.

We help create professional managers who will lead the next Monozukuri generation.About TPS and Lean

Nearly 30 years ago, Lean was presented as the generic version of TPS.

Actually, Lean was an interpretation of TPS – a rather poor interpretation.

Then, over time, Lean drifted farther away from TPS, thus making it far less of a generic version of TPS and more its own unique thing.

“Difference”

The lean production method is packaged even as a production management method, and a set of texts, checklists, and standards required for introduction is provided as a package from a consulting company.

On the other hand, TPS is a production method that has been established to thoroughly eliminate waste on the production line.

It is a method that has been systematized based on the two pillars of “just-in-time” and “automation” in order to define seven wastes and eliminate them.

DAY 4

Toyota Motor Corporation - Factory tour -

- -----

-

Company : Toyota Motor

Corporation

Establishment : 1937

Location : Aichi Prefecture

Main Business : AutomotiveThe Toyota Production System is considered to be the final production control method, which has led Toyota to be the most competitive motor company in the world.

Every company in the world is interested in whether to implement the Toyota Production System to their system.

Visitors must make their own reservations at the Toyota Motor Factory.

Factory tour reservations can be made from the Toyota Motor Corporation website.

In accordance with the factory tour time, we will transfer you from the hotel to the factory tour. - 10:30

-

Toyota Kaikan Museum

An introduction to

Toyota’s approach to vehicles

from a variety of perspectives. - 11:00

-

Toyota factory

During the tour, visitors will be shown the Assembly Plant.Notes on factory tours.

If you do not observe the precautions, the factory tour will be canceled.- Photographs on the factory premises, VTR

- Bringing electronic devices such as cameras, mobile phones, Wi-Fi routers, etc. into the factory buildingSmoking, eating and drinking (only water bottles with lids and plastic bottles can be brought in for hydration)

- Sandals, footwear such as high heels over 5cm

- Drinkers

- Children under 6 years old and children under 12 years old without parental supervision·

- Passenger who factory arrival on car or foot, admission.

- 13:00

-

The Toyota factory tour is over.

Lunch time and return to Nagoya city. - 17:01

-

Depart from Nagoya staition.

- 17:35

-

Arrived at Kyoto station.

DAY 5

Free time in Kyoto city

- -----

-

Free time in Kyoto.

DAY 6

Return day : From Kyoto to Kansai Airport

- 10:00

-

Depart from Kyoto station.

- 11:20

-

Arrive at Kansai Airport.

Destination

Osaka

Osaka, the largest city in western Japan.

The food culture that became the basis of Japanese cuisine flourish, and the birthplace of authentic Japanese cuisine such as shabu-shabu and kaiseki cuisine. Takoyaki and okonomiyaki are also popular.

Attractions such as downtown area such as Kita Minami, Osaka Castle, and unique power and humanistic culture are also attractive.

Kyoto’s Shinkansen is a 30-minute ride away, and many tourists visit it as a tourist base in western Japan.

Reviews

The consultant's seminar was good!

Food processing plant

Singapore 8 people

am interested in recycling industrial waste personally and participated in the seminar tour.

The industry is different, but I was surprised to see the recycling factory.

Not only that technology but also management that leads to raising the problem was wonderful.

I was able to know Japanese environmental technology.

Manufacturing industry

Vietnam 20 people

In order to reform our factory with the aim to create an environmentally conscious factory,

I visited a Japanese company for our reference.

Satisfied with medical checkups and hot springs.

Parts processing company

China 4 peopleI could spend less time to stay in Japan effectively. The place to visit was inconvenient to access by myself. That's why I participated in the tour and I was also able to attend consultant seminars.

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays