Overview

This is a course to incorporate TPS into your factory.

Venue : Your factory

Period : 3DAY or 4DAY

Consultant : An excellent improvement consultant with experience in improvement at factories around the world.

Expenses : In addition to consulting fees, prepare a flight from Japan to the airport near you, a factory interpreter specialist, and a hotel where consultants will stay.

TPS is not a manual.

Rather it is an overview of the concepts, that underlie production system.

Kaizen never end

The TPS is a framework for conserving resources by eliminating waste. People who participate in the system learn to identify expenditures of material, effort and time that do not generate value for customers and furthermore we have.

Recommended for people like this

Manufacturers considering the introduction of TPS and Lean production systems in their factories.

Tour Remarks

Cancellation Policy

-

※ The handling fee for refund will be paid by the customer.

※ If the number of people in the hotel room or the room type changes due to a reduction in the number of participants, additional charges will be required.

Person in charge

Miki Shimizu

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

Dates & Price

Tour Code: K25-3d

DAY 1

business meeting

- 13:00

-

Consultants and staff arrived from Japan.

Visit your factory, We will discuss about factory diagnosis and seminars of the next day.

You have to prepare a professional interpreter in the factory.

DAY 2

TPS Seminar

- 09:00

-

09:00-16:00

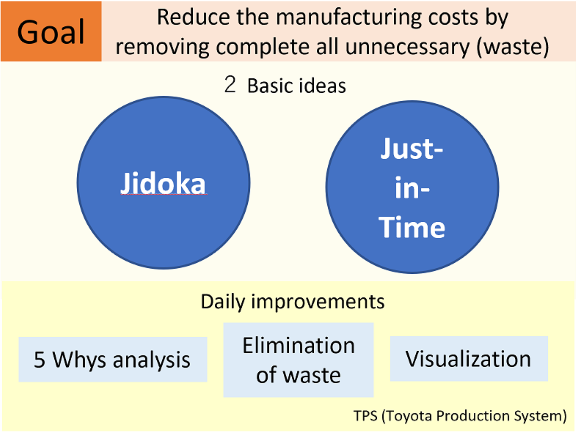

About TPS (Toyota Production System)TPS is an integrated production-technical system, developed by Toyota, that comprises its management philosophy and practices.

The system is a major precursor of the more generic “lean manufacturing”.

Taiichi Ohno and Eiji Toyoda, Japanese industrial engineers, developed the system between 1948 and 1975.Two important ideas of TPS

1 ) Just in time : meaning “Making only what is needed, only when it is needed, and only in the amount that is needed”

2 ) Autonomation(Jidoka) : meaning “Automation with a human touch”

DAY 3

Factory diagnosis

- 09:00

-

Started factory diagnosis.

In the first factory diagnosis, we strongly encourage the participation of management team, including the president of your company.

Inspect the entire factory with consultants.The most important thing

All employees feel that the company management is seriously trying to improve the factory.

Employees cannot continue to improve unless the company management changes.

And it cannot be continued unless it is reflected in the personnel evaluation system. - 13:00

-

13:00-15:30

Discussion - -----

-

About Hirayama Consulting

Do KAIZEN from the costumer’s perspective, improving the technologic, quality and cost competitiveness, aiming to build a low-cost production site”. This is our Mission.

Our Consultants implement the TPS (Toyota Production System), providing a real effective Consulting Service in domestic and international.Consulting Example

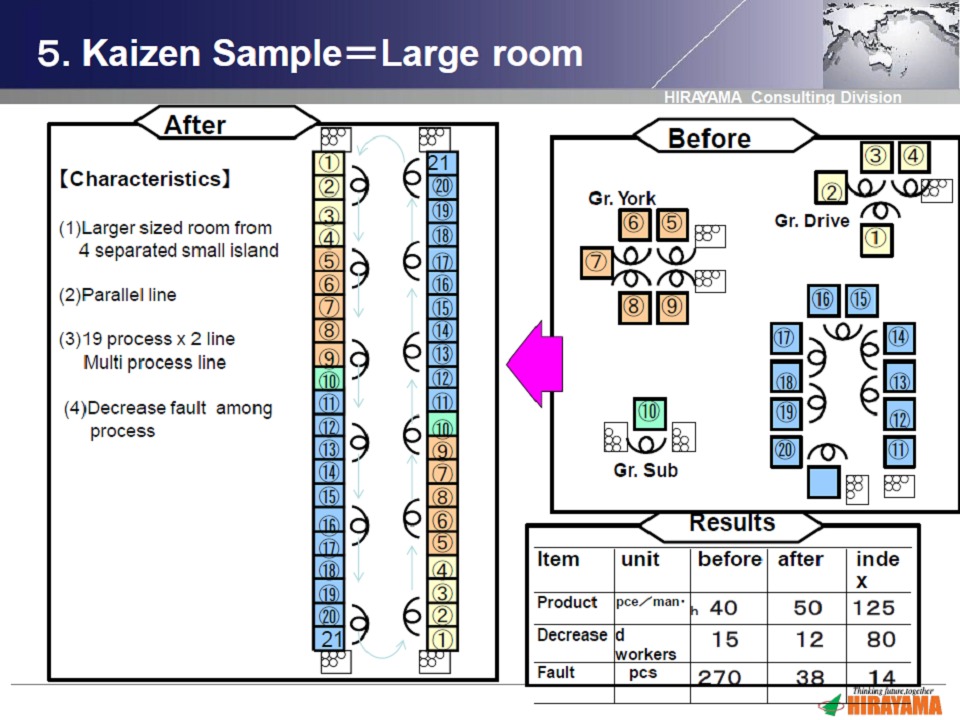

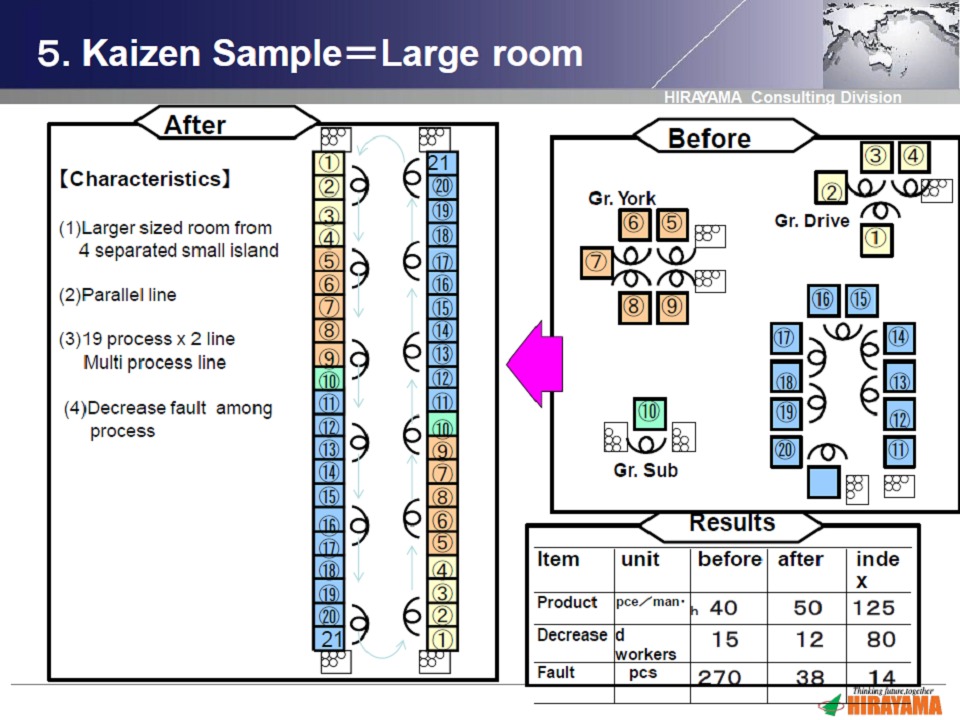

Line-Kaizen sample

Larger sized room、Multi process line、 Cell line system、Truck production, etc

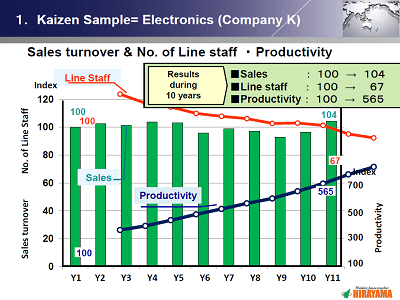

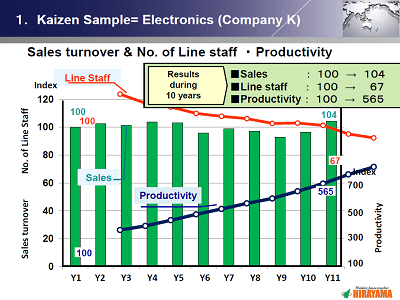

Kaizen Sample= Electronics (Company K)

Tour Code: K25-3d

DAY 1

business meeting

- 13:00

-

Consultants and staff arrived from Japan.

Visit your factory, We will discuss about factory diagnosis and seminars of the next day.

You have to prepare a professional interpreter in the factory.

DAY 2

Seminar

- 09:00

-

09:00-16:00

About TPS (Toyota Production System)TPS is an integrated production-technical system, developed by Toyota, that comprises its management philosophy and practices.

The system is a major precursor of the more generic “lean manufacturing”.

Taiichi Ohno and Eiji Toyoda, Japanese industrial engineers, developed the system between 1948 and 1975.Two important ideas of TPS

1 ) Just in time : meaning “Making only what is needed, only when it is needed, and only in the amount that is needed”

2 ) Autonomation(Jidoka) : meaning “Automation with a human touch”

DAY 3

Factory diagnosis Day1

- -----

-

Started factory diagnosis.

In the first factory diagnosis, we strongly encourage the participation of management team, including the president of your company.

Inspect the entire factory with consultants.The most important thing

All employees feel that the company management is seriously trying to improve the factory.

Employees cannot continue to improve unless the company management changes.

And it cannot be continued unless it is reflected in the personnel evaluation system. - 13:00

-

13:00-15:30 Discussion

- -----

-

About Hirayama Consulting

Do KAIZEN from the costumer’s perspective, improving the technologic, quality and cost competitiveness, aiming to build a low-cost production site”. This is our Mission.

Our Consultants implement the TPS (Toyota Production System), providing a real effective Consulting Service in domestic and international.Consulting Example

Line-Kaizen sample

Larger sized room、Multi process line、 Cell line system、Truck production, etc

Kaizen Sample= Electronics (Company K)

DAY 4

Factory diagnosis Dai2

- 09:00

-

In the case of a factory with more than 200 people, a two-day factory diagnosis is recommended.

- 13:00

-

Discussion

Destination

Around the world

We can conduct TPS seminars and corporate cost reduction consulting in cities around the world.

For example, we have visited and implemented China, Vietnam, Malaysia, Germany and Mexico frequently in 2019-2020.

In other countries, such as India, Indonesia, Singapore and Cambodia, we have been consulting for manufacturing, forestry and restaurants for over 10 years.

Reviews

Excellent consultant

Wood pulp

indonesia 55 peopleStarting from the processing factory, all improvements were made in about two years, including the timber growing field. Very satisfied. However, it is difficult to continue this improvement activity even after the consultant is gone. I feel that the company needs an opportunity to continue this activity.

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays