Overview

Reasons why we recommend “Karakuri Kaizen”

Very fun,low cost,and Has a positive impact on the workplace.

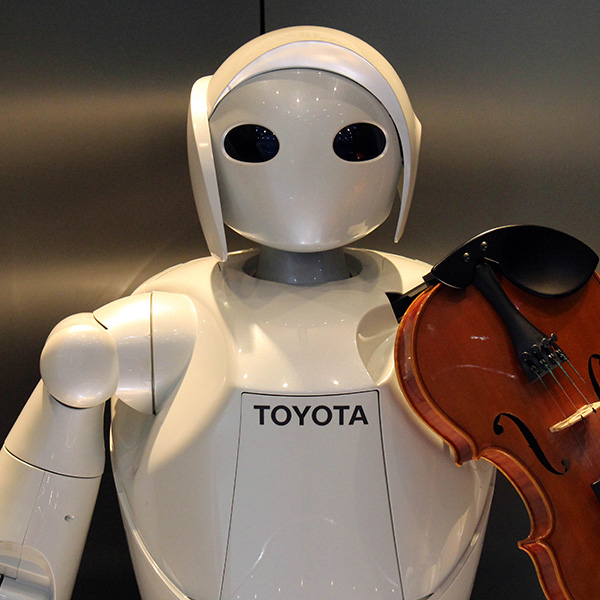

Karakuri Kaizen made with small material costs and low power.

Seminar content

1. About TPS

About TPS and Lean

Nearly 30 years ago, Lean was presented as the generic version of TPS.

Actually, Lean was an interpretation of TPS – a rather poor interpretation.

Then, over time, Lean drifted farther away from TPS, thus making it far less of a generic version of TPS and more its own unique thing.

“Difference”

The lean production method is packaged even as a production management method, and a set of texts, checklists, and standards required for introduction is provided as a package from a consulting company.

On the other hand, TPS is a production method that has been established to thoroughly eliminate waste on the production line.

It is a method that has been systematized based on the two pillars of “just-in-time” and “automation” in order to define seven wastes and eliminate them.

2. What is Muda (waste), Mura (unevenness), and Muri overburden) in Factory.?

3. A simple mechanism for Karakuri Kaizen

4. Karakuri KAIZEN example

Even if you try to start making Karakuri Kaizen on your own, it is difficult.

Let’s start by imitating togher!

5. Failure examples of karakuri KAIZEN

Recommended for people like this

Tour Remarks

Cancellation Policy

-

※ The handling fee for refund will be paid by the customer.

※ If the number of people in the hotel room or the room type changes due to a reduction in the number of participants, additional charges will be required.

Person in charge

Miki Shimizu

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays

Dates & Price

Tour Code: K11-1d

DAY 1

Karakuri Kaizen Seminar

- -----

-

Seminar

09:30-12:30 0r 13:30-16:30

We can hold it on your schedule. - -----

-

About consultant

OBARA, Shigeyuki(RICOH)RICOH Production Engineering Department

In RICOH, he implemented the Kaizen (improvement) education to the managers and the employees.

Perform the improvement activities by himself at the actual work-site.

After that, transferred to the Consulting department for companies outside RICOH, and carried out Worksite Diagnosis and Consulting for the varieties of industries.

Specialized in varieties of industries, to regularize the improvement of work-sites, to develop improvement Key-man through the improvement activities, and to improve qualities, to improve productivity and to shorten a lead-time.

Specialized in , Regardless of a type of industry, establish work-site improvement and realize shortening through an improvement activity in improvement keyman upbringing and quality improvement, productivity improvement, lead time.

Destination

Around the world

We can conduct TPS seminars and corporate cost reduction consulting in cities around the world.

For example, we have visited and implemented China, Vietnam, Malaysia, Germany and Mexico frequently in 2019-2020.

In other countries, such as India, Indonesia, Singapore and Cambodia, we have been consulting for manufacturing, forestry and restaurants for over 10 years.

Reviews

The consultant's seminar was good!

Food processing plant

Singapore 20 people

am interested in recycling industrial waste personally and participated in the seminar tour.

The industry is different, but I was surprised to see the recycling factory.

Not only that technology but also management that leads to raising the problem was wonderful.

I was able to know Japanese environmental technology.

Manufacturing industry

Vietnam 20 people

In order to reform our factory with the aim to create an environmentally conscious factory,

I visited a Japanese company for our reference.

Satisfied with medical checkups and hot springs.

Parts processing company

China 40 peopleI could spend less time to stay in Japan effectively. The place to visit was inconvenient to access by myself. That's why I participated in the tour and I was also able to attend consultant seminars.

Click here for the booking and inquiry about the tour.

Book this tour Inquire about this tourIf you are in a hurry, please call us. +81 03-5783-3571 Open 08:30 - 17:30

Except for Saturday, Sunday, holidays, Year-End and New-Year holidays